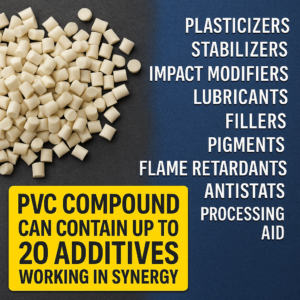

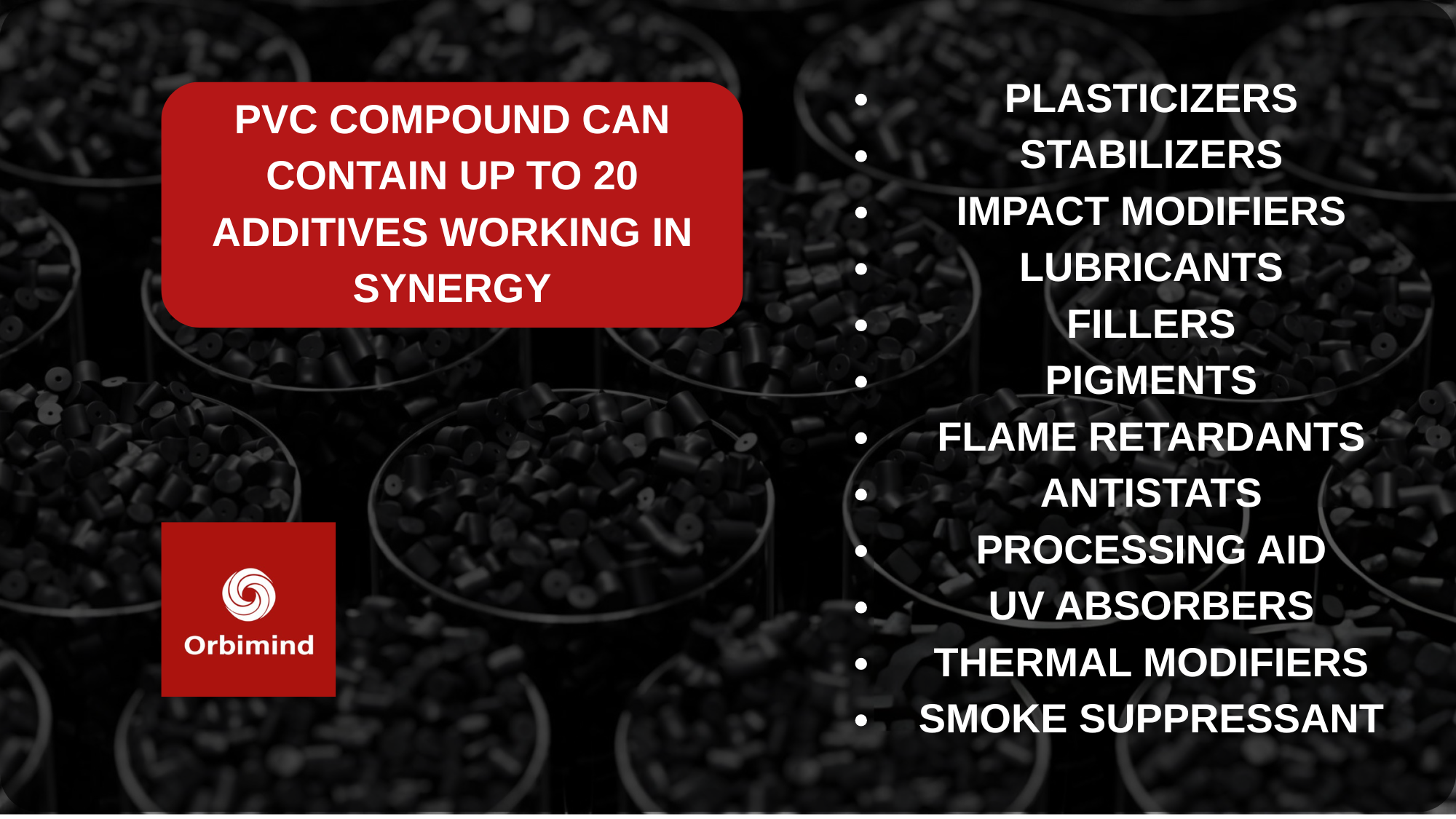

Did you know a single PVC compound can contain up to 20 additives, all interacting with each other in complex ways?

From plasticizers and stabilizers to impact modifiers, lubricants, fillers, pigments, and flame retardants, each additive plays a vital role in shaping the performance and processing characteristics of PVC.

Yet here’s the catch: ⚠️ Change one, and you may affect them all.

🔍 How Additives Interact in PVC Compounding

PVC is unique among thermoplastics for its compound design flexibility, but also its formulation sensitivity. A minor tweak to a single component can ripple across the whole system.

For example, adjusting just one additive might:

- 📉 Shift fusion torque, affecting how the material processes

- 🎨 Alter color stability, leading to inconsistency in the final product

- 🧪 Spike VOC emissions, potentially affecting regulatory compliance

- 🏗️ Undermine mechanical durability, especially over long-term service

That’s why PVC formulation isn’t just about swapping ingredients — it’s a finely tuned ecosystem where chemical interactions are everything.

🧠 Why PVC Additive Synergy Matters

The synergy between additives is not theoretical — it’s what determines the success of cable insulation, weatherability of window profiles, or the flame resistance of flooring materials.

Getting the balance wrong can:

- Cause melt fractures

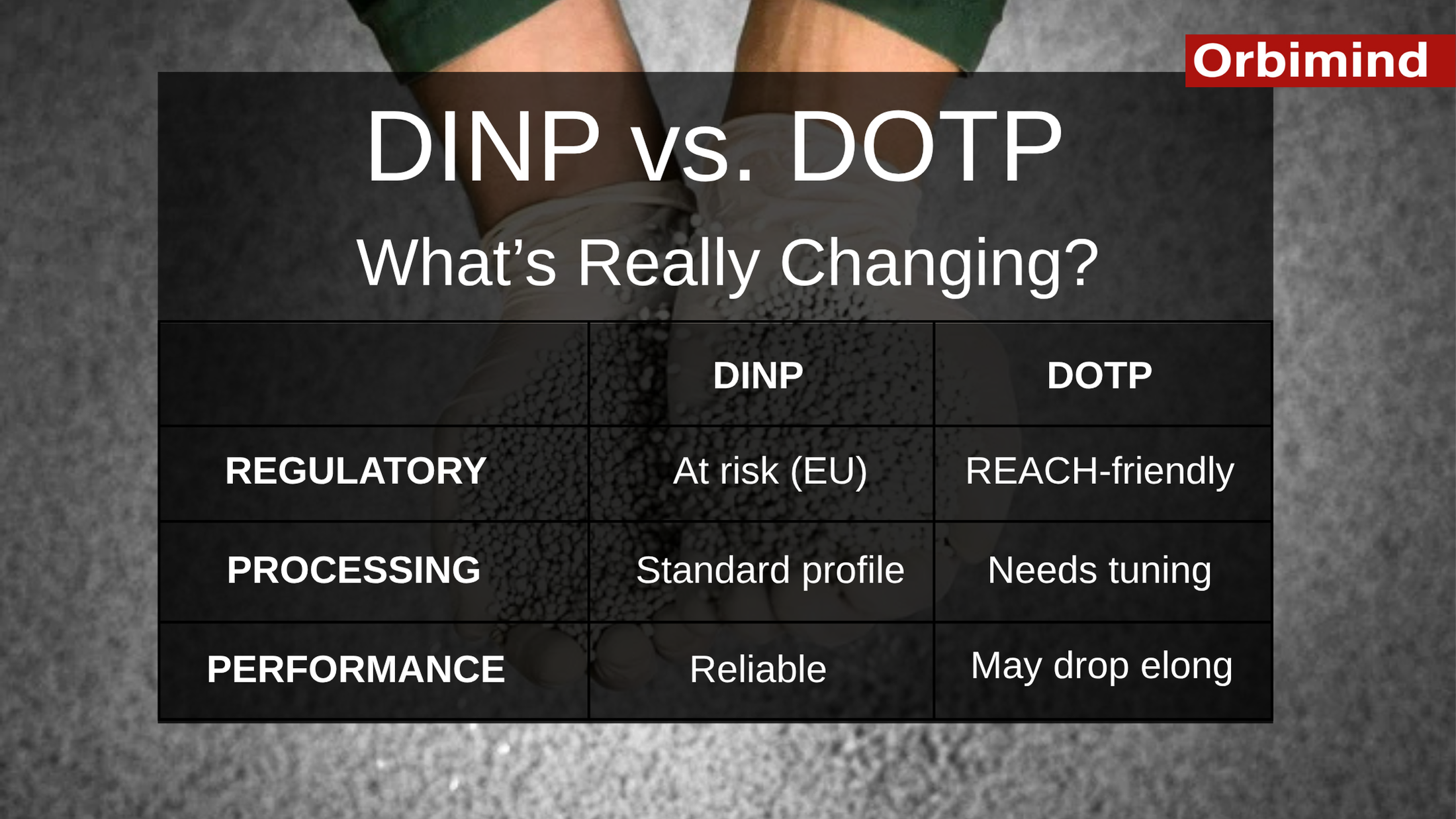

- Fail REACH or RoHS compliance

- Increase cost per kg with no performance gain

On the other hand, understanding the interplay of additives unlocks:

- 💡 Lighter formulations without performance drop

- 🌱 Sustainability gains (like reducing heavy metals or replacing legacy phthalates)

- ⚙️ Process efficiency and energy savings in extrusion lines

💬 So, How Many Additives Are in Your Most Complex PVC Formulation?

Are you dealing with 6? 12? 18?

And more importantly — are they working together or against each other?

🔗 Learn More at Future of PVC 2026

If you’re working in formulation, R&D, or technical marketing for PVC-based products, join us at the Future of PVC 2026 conference in Frankfurt, March 11–12.

🧪 Discover:

- Next-gen stabilizer systems

- Data-driven formulation optimization

- Circular additive strategies for recycled PVC